If your processing plant is experiencing diminished overall efficiency due to suboptimal crushing performance, the root cause often lies in a mismatch between the crushing process and the ore's characteristics.

The true solution lies in selecting a crusher that is deeply suited to the specific properties of your ore body and capable of delivering long-term, stable operation.

I: The Importance of Gold Ore Crushing

1. Aligning with Subsequent Processes

Truly efficient crushing does not lie in processing ore to the finest possible size. The key lies in ensuring the resulting particle size precisely matches your subsequent mineral processing stages (grinding, flotation, gravity separation, or leaching).

2. Impact on Gold Recovery Efficiency

As gold is embedded within the ore matrix, inadequate liberation due to improper crushing may result in a predicament where gold is visible yet difficult to recover, regardless of the subsequent beneficiation method employed.

Gold ores vary immensely in composition, and each type of crusher is designed with a specific application range. No single piece of equipment in the world can handle all ores indiscriminately.

II. There is no such thing as a ‘universal’ gold ore crusher

Please assess the gold ore at your mine site:

If you are dealing with high-hardness quartz vein gold ore, a robust abrasion-resistant crushing solution is required;

If you are processing moderately soft oxidised ore, excessive crushing may result in gold particles becoming too fine for efficient recovery;

If your ore contains high levels of clay, sticking and clogging will persistently plague conventional crushers;

If your extraction points are dispersed and variable, fixed production lines will struggle to meet the demands of flexible mobile operations.

Therefore, a tailored crushing solution can help you achieve higher recovery rates, lower costs per tonne of ore, and accelerate your investment return cycle.

III. Detailed Analysis of Four Core Crushing Equipment for Gold Mining

Jaw Crusher: Primary Crushing of Gold Ore

The jaw crusher serves as the initial stage of your crushing process, specifically engineered to handle large, hard raw ore (such as quartz vein-type gold deposits).

Advantages:

Extremely low failure rate; capable of sustained high-intensity impact crushing.

Superior structural rigidity: High-strength frame withstands immense crushing forces, tackling the hardest gold ores.

Exceptional adaptability: Insensitive to material moisture or stickiness; reliably starts even with slightly muddy ore.

Simple maintenance, low operational costs: Durable core components like the moving jaw ensure straightforward daily upkeep and outstanding long-term economic performance.

Core Parameters:

Maximum feed size for gold ore: ≤1200mm.

Discharge size for gold ore: 10-350mm.

Processing capacity: 50-1000 tonnes per hour.

Please note: Jaw crushers are exclusively designed for primary crushing stages and must not be employed for secondary or tertiary crushing. Doing so will result in inconsistent product gradation, increasing subsequent grinding loads and associated costs.

Cone Crusher: Medium-Fine Crushing of Gold Ore

The cone crusher serves as the core equipment for medium-fine crushing in medium-to-high hardness gold ore. Characterised by its high crushing ratio, uniform output, and exceptional wear resistance, it typically forms a complete ‘primary crushing + medium-fine crushing’ process when paired with a jaw crusher, representing a critical step in enhancing overall recovery rates.

Advantages:

Superior particle shape with low over-crushing rate: Laminar crushing produces more uniform cubic particles, facilitating gold particle liberation and leaching while effectively protecting fine gold grains.

High production efficiency and stable operation: The hydraulic system provides overload protection and automatic cavity clearance, ensuring continuous, stable production with low energy consumption per unit.

High degree of automation: Easily integrates with automated systems to achieve automatic discharge adjustment and load control, optimising the entire process.

Core Parameters:

Gold ore feed size: ≤450mm

Gold ore discharge size: 5–40 mm

Processing capacity: 50–300 tonnes per hour.

Please note: This equipment is sensitive to clay content. Should your ore exhibit high clay content (>8%), blockages may occur; exercise caution when selecting this model.

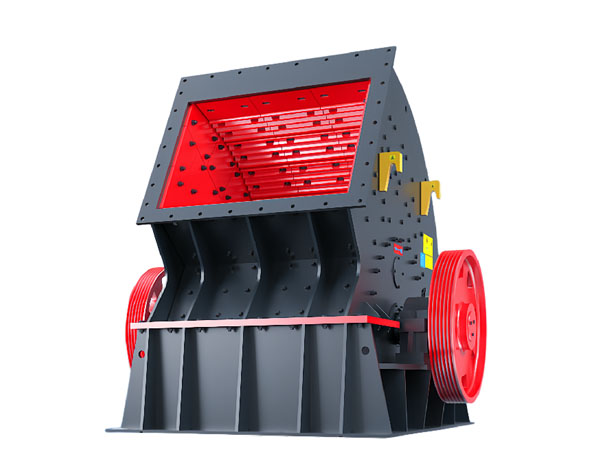

Hammer Crusher: Single-Stage Crushing

The hammer crusher offers a ‘single-stage crushing’ solution for medium to low-hardness ores (such as metamorphic rock types), achieving finer products through a single crushing stage. This simplifies the process flow and presents a low investment threshold.

Advantages:

High crushing ratio, single-stage forming capability: Can reduce large ore blocks to under 25mm in a single pass.

Low equipment investment: Simplified process flow with minimal ancillary equipment reduces initial capital expenditure.

Intuitive operation and maintenance: Relatively straightforward structure facilitates easy understanding and operation. Key Considerations and Parameters:

Core Parameters:

Gold ore feed size: ≤800mm (capable of handling larger lumps).

Gold ore discharge size: ≤50mm

Processing capacity: 50-1000 tonnes per hour.

Please note: Hammer crushers are unsuitable for hard rock gold ore. When used for hard rock crushing, hammer wear is extremely rapid, leading to significantly increased operational costs.

Mobile Crushing Plant

For mines with multiple sites or dispersed ore bodies, fixed crushing production lines often lack flexibility, leading to increased operational complexity and costs.

Mobile gold crushing stations can operate directly at the mining face, significantly reducing ore transport distances—thereby helping you effectively control haulage costs, which typically constitute the largest share of mining operational expenditure.

Core Parameters:

Main Unit Configuration: The mobile crushing plant can be flexibly configured with core units such as jaw crushers, cone crushers, or impact crushers according to specific requirements.

Drive System: The mobile crushing plant offers two configurations: tracked (fully hydraulic drive, strong off-road capability) or wheeled (requires semi-trailer towing, flexible deployment).

Power Options: Mobile crushing plants feature diesel or electric drive options to comprehensively meet operational requirements.

Note: Mobile crushing plants are most suitable for small to medium-scale production capacities (e.g., 50-500 tonnes per hour). For large-scale mining operations, fixed crushing production lines equipped with stationary crushers offer superior cost-effectiveness.

IV. Practical Case Study: Zimbabwe 100 Tonnes Per Hour Hard Rock Gold Mine Project

Project Challenge: The deposit primarily consists of hard quartz vein-type gold ore, with maximum raw ore particle size reaching 650mm. The target crushed product size is -25mm.

Solution:

Primary Crushing Stage: Deployed a large jaw crusher to reliably process large raw ore blocks.

Secondary and Tertiary Crushing Stage: Employed a series of multi-cylinder hydraulic cone crushers in tandem for efficient secondary and tertiary crushing operations.

Closed-Circuit Screening: Ensured final product particle size compliance rate >95%.

Implementation Outcomes:

The system has operated stably for three years, achieving an 18% reduction in total crushing energy consumption and a 30% increase in liner lifespan beyond industry averages. It delivers an ideal feed size for subsequent leaching processes.

V. Action Guide: Selecting Your Tailored Crushing Solution

While there is no universal answer for gold ore crushing, a scientific approach to selection exists:

If you are in the project planning phase, we recommend:

Provide detailed mechanical property test reports for your ore (hardness, compressive strength, SiO₂ content, etc.)

Define your production capacity targets, product size requirements, and site conditions

Arrange one-to-one operational alignment with our technical engineers

If your existing crushing line exhibits issues (e.g., substandard output, accelerated wear, suboptimal product size), we recommend booking our on-site diagnostic service. Our engineers will visit your facility to deliver tailored optimisation solutions.